Somebody said: I am thinking about fitting out a container ship for a fabrication site…

A container ship is probably one of the best options when going for a ship - they are basicly open without divisions and deck ( a big empty canoe if you want to see it that way) which is a good starting point.

On the other hand you will get the same problems as you had with the Satoshi - after all it is a SHIP and as a ship it has to apply to extremly expensive and very detailed “obligated shedules” to “keep it in class” and once it “falls out of class” no port and no anchorsite will welcome you.

The marine industry is used to the line of thinking that “ship out of class is environment hazard in fast progress” -

You have a kind of “narrative and perception issue” that is hard to deal with. Explaining that your “ship is not exactly a ship” and deserves to be treated different - is much harder and expensive than doing something that floats but is “clearly outside of shipping industry parameters”

So to start with you might want to look for something that floats and that is “clearly not a ship” so free of that kind of obligations and complications.

You might go for a Barge - they are in less strict frameworks - but still in narrow perception and rule frameworks after all.

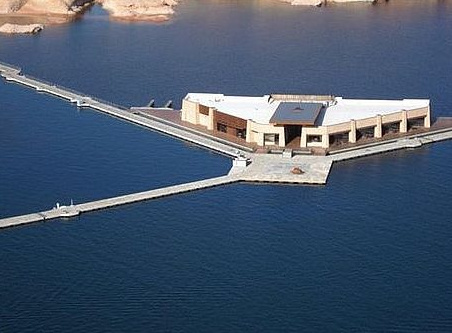

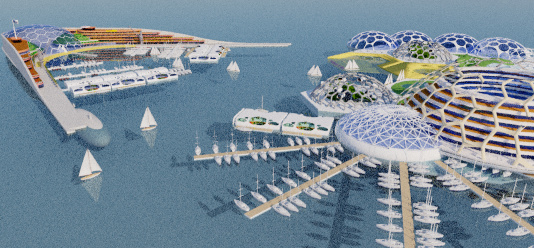

What you want as a base for a fabrication site is something that can pass as a “floating island” or a “marina walkway installation” that is clearly outside of the radar of the kind of “ruling sets” and enforcement agencies that deal with ships.

seasteading core thesis:

• “Never ever and under no circumstances call it a ship”

…or allow that it gets treated like a ship…

The moment you get lumped in with “ship rule sets” or “oil platform rule sets” your project is baked - due to unfeasibility of the resulting cost structure.